All electrical applications, including inductors, systems for converting renewable energy sources, and energy storage, need the usage of power converters. The urgency of electrifying systems that formerly relied on burning fossil fuels has increased as global attempts to reduce greenhouse gas emissions pick up speed. As the globe evolves toward the use of electric systems powered by renewable energy, converter efficiency and performance—the main component of these systems—become more and more important.

Hillcrest Energy Technologies wants to set an example for others to follow in decarbonizing the energy industry by assuming a market position in the energy transition. Its technology is concentrated on developing solutions that maximize the performance of integrated electric systems and release electrification efficiencies. While we are concentrating on traction inverter technology for electric vehicles (EVs), Chief Technology Officer Ari Berger at Hillcrest indicated that the solutions we are creating may also be applied to a wide range of sectors to improve the efficiency of electrical systems.

The use of higher switching frequencies has previously resulted in a bigger increase in losses, including decreased system efficiency and increased heat, according to Berger, but Hillcrest technology eliminates traditional design tradeoffs experienced across the power industry. According to Berger, “Hillcrest technology materially eliminates switching losses through a combination of hardware and control software expertise, enabling power applications to leverage higher switching frequencies, realize improved power system performance and reliability, and operate at higher power levels without compromising efficiency.”

Inverter technique based on SiC

Hillcrest’s inverter technology lowers inverter losses, which lowers the amount of thermal management required throughout the entire powertrain system. This might save a lot of money because it would simplify the system and take some of the strain off the power components.

Conduction losses have been reduced with the development of silicon-based technologies like MOSFETs. Low-conducting-resistance switches have also been created recently using silicon carbide and gallium nitride, two wide-bandgap semiconductors. By shortening the transition time, these also lessen switching losses, however this has led to EMI problems and high dV/dt, which have a negative impact on dependability.

By removing the current and voltage transition overlap, switching losses can also be decreased or eliminated. The widely used method relies on zero-voltage switching (ZVS).

“Soft switching,” made possible by ZVS, eliminates switching losses that frequently happen with conventional PWM and synchronization.

Any voltage or current overlap is eliminated during soft switching of a MOSFET, lowering losses. Before the MOSFET is turned on or off, the voltage decreases to zero (and not merely to idle). (The technique can also be used to flip the MOSFET when the current instead of the voltage gets close to zero. This method is known as ZCS, or zero-current switching.) Another advantage of soft-switching waveforms is the reduction of EMI.

The conversion of regular PWM power while the MOSFET is operating but with “resonant” switching transitions is the most accurate description of soft switching (ZVS). A PWM power supply that uses a continuous control to change the conversion frequency or maintain output voltage regulation over time may be used as a comparison for the method. For a specific unit of time, this method is comparable to fixed-frequency conversion with adjustable duty cycle.

The ability of ZVS to work at higher frequencies, which results in less noise, simpler filtering, and the need of fewer filter components, as well as its capacity to lower the harmonic spectrum of any EMI are two further advantages of ZVS (by focusing it on the switching frequency).

The drawback, especially at high frequencies, is that there is no guarantee that the MOSFET will have expended all of its energy before shutting down. A fast-switching voltage regulator in particular may experience component breakdown as a result of this “stored” energy over time. Power module manufacturers address this problem by interconnecting a fast body diode in parallel with the switch in order to guarantee that all energy is released from the transistor.

The current ZVS techniques have limitations, including performance that is temperature and load dependant and an operating range that is too small, making them unsuitable for traction applications. The ZVS approach is implemented by Hillcrest’s inverter technology, which uses cutting-edge control software algorithms and microcontrollers. This technique makes soft switching possible and substantially reduces switching losses. Therefore, with switching losses removed, the converter’s switching frequency may be raised, and the system can benefit from a high switching frequency by having greater performance and a lower overall size.

According to Harald Hengstenberger, Managing Director and Founder of Systematec GmbH, a strategic partner of Hillcrest with expertise in power electronics and electromechanical component design, “We are currently using 1,200-V SiC semiconductors for our developments because they are currently the most suitable for traction applications.” The switching frequencies of today’s traction systems, he observed, are around 10 kHz. We see significant benefits in variable adjusting this switching frequency to the ideal value for total system efficiency, which is up to about 100 kHz, utilizing our high-efficiency inverter technology. GaN switches are used in chargers and DC/DC converters because they are suitable for significantly greater switching frequencies.

According to Hilllcrest, this kind of inverter could be useful in any market with long working times or high efficiency needs. “The Hillcrest inverter technology platform can improve efficiency and reliability across a variety of end uses and applications in which inverters play a key role, including grid-tied renewables, charging and storage systems, and high-voltage/high-power applications like utility-scale grid, rail, and container ships,” said CTO Berger. “In addition to electric vehicles and the mobility industry.

Higher switching frequencies are possible thanks to Hillcrest’s inverter technology’s substantial elimination of switching losses, which improves output power quality, reduces overall harmonic distortion, and allows for smaller DC-link capacitor sizes. Additionally, without negatively affecting losses, it lowers the dV/dt of the main power switches, preventing insulation breakdown in motor windings and cable and reducing issues typically brought on by EMI.

Hillcrest claims that these advantages provide important system-level advantages like decreased motor size and cooling needs, lower torque ripple, and longer mechanical part lifetimes in traction applications.

The lowest forward losses and good switching qualities are typically compromised when developing semiconductors, according to Berger. “Since the switching losses of power semiconductors have essentially been eliminated by our high-efficiency inverter technology, future generations of semiconductors that are tailored for the lowest feasible on-state losses should result in significant improvements in efficiency and range. Hillcrest’s high-efficiency inverter technology also uses a unique switching technique that lowers the ripple current in the DC circuit, which helps lengthen battery life. The type of semiconductor is not crucial in this regard, in our opinion.

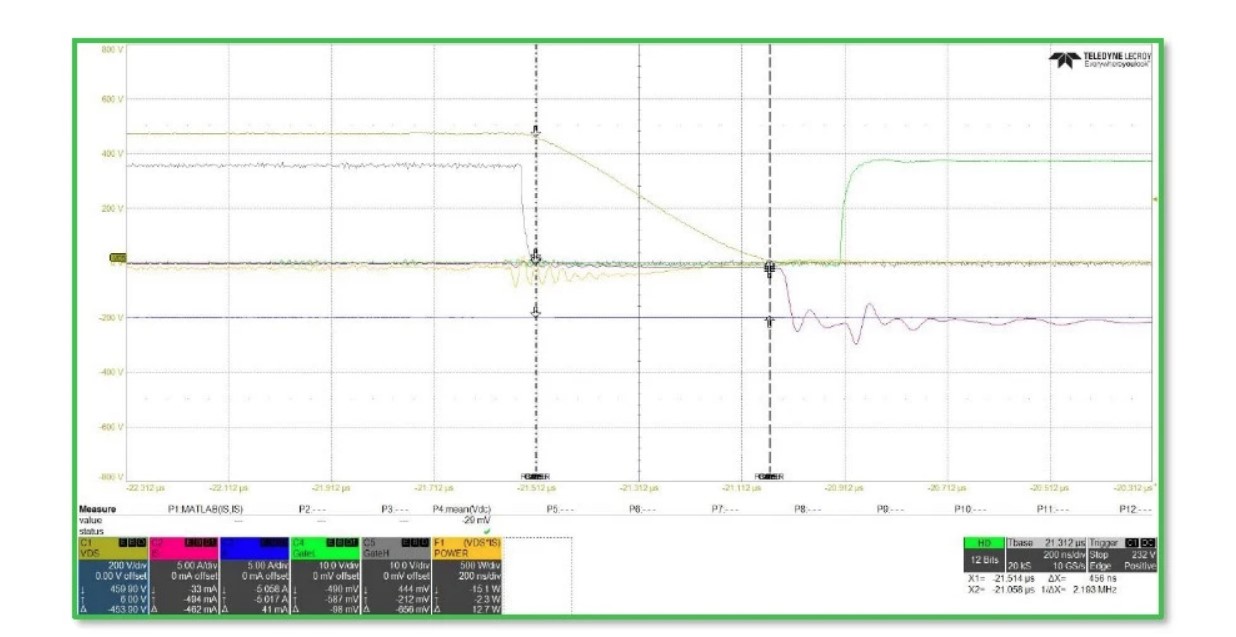

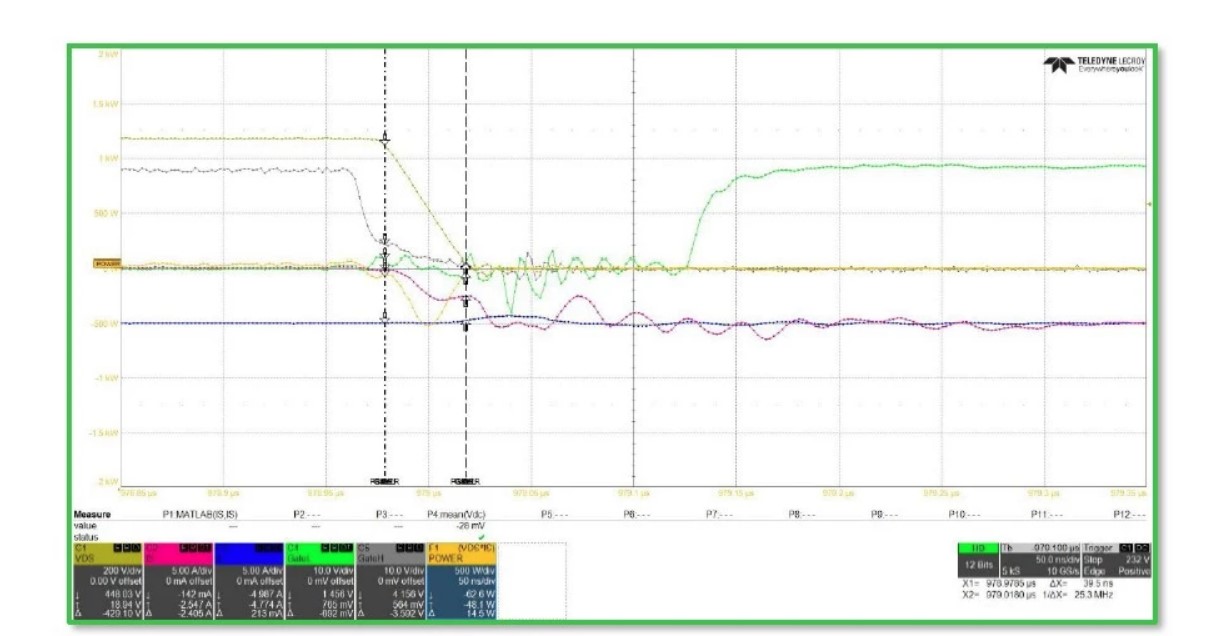

Results for the turn-off transition under 5-A current toward the converter are shown in Figures 1 and 2. (negative direction). In the hard-switching technique, the switch with a 1.5 kW peak power dissipates about 65 J. The dV/dt in this design is roughly 13 kV/s, which is highly high and dangerous for cables and motors. However, the losses of the soft switching during the transition are remarkably minimal, at just 2 J. This scheme’s dV/dt value of 1.1 kV/s results in longer cable and motor life, lower EMI, and less shielding requirements.

Challenges

Size, weight, and cost are consistently the key forces behind inverter development. The interaction and trade-offs between these three needs in respect to one another determine a device’s ultimate efficiency.

According to Berger, “by eliminating the switching losses, an inverter’s already high efficiency of 97.5% to 98% is boosted by another 1.5%. “While improved inverter efficiency is advantageous, the inverter’s greater switching frequencies are the key advantage. The quality of the supply current for the electric machine is significantly improved by raising the switching frequency of the inverter, and the system efficiency is raised by about 14% in the partial load range, which therefore has a much more significant impact on range.

Hillcrest claims that by making some components smaller, its inverter technology can aid in easing the difficulties associated with packing. According to Berger, “For product design, our partner Systematec has many years of experience in the hardware design for the automotive industry, and we also want to partner/collaborate with technology businesses that specialize in this area, including global Tier 1 automotive suppliers and OEMs.”

Tech Gadget Central Latest Tech News and Reviews

Tech Gadget Central Latest Tech News and Reviews