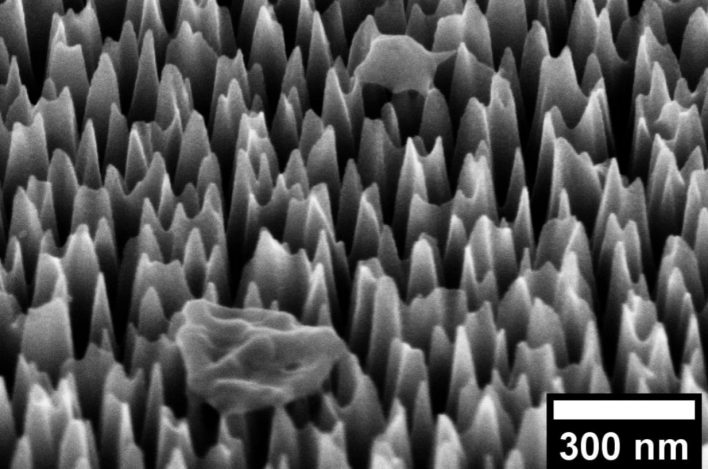

A virus on the nano-spiked silicon surface is 65,000 times bigger than it really is. It has already started to leak after an hour.

A group of researchers from around the world, led by RMIT University, has created a surface that kills viruses. This could help stop the spread of disease in hospitals, labs, and other high-risk places. The silicon surface is covered with very small spikes called nanospikes that poke viruses when they touch them.

When the hPIV-3 virus, which causes asthma, pneumonia, and croup, was tested in the lab, 96% of the viruses were broken up or weakened so much that they could no longer infect others. These amazing results, which were featured on the cover of the top nanoscience journal ACS Nano, show that the material could help stop the spread of possibly harmful biological material in healthcare settings and labs.

Kill the bugs by giving them a boost.

The corresponding author, Dr. Natalie Borg from RMIT’s School of Health and Biomedical Sciences, said that this simple idea of skewering the virus needed a lot of technical know-how.

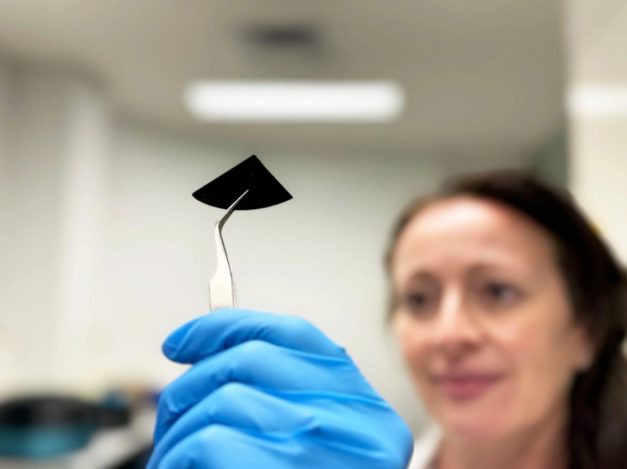

“To the naked eye, our virus-killing surface looks like a flat black mirror, but it has tiny spikes that are designed to kill viruses,” she said. “This material can be added to surfaces and devices that people often touch to stop the spread of viruses and cut down on the need for disinfectants.”

The nano-spiked surfaces were produced at the Melbourne Centre for Nanofabrication, beginning with a silicon wafer of uniform texture. This wafer was subjected to ion bombardment in order to selectively eliminate material. The outcome is a surface replete with needles measuring 2 nanometers in thickness, which is 30,000 times smaller than the diameter of a human hair, and measuring 290 nanometers in height.

Antimicrobial surface specialists

The RMIT Distinguished team lead by Professor Elena Ivanova has extensive expertise in the field of mechanical techniques used for the management of harmful microorganisms, drawing inspiration from natural phenomena. Notably, the wings of insects, such as dragonflies or cicadas, have a nanoscale spiky configuration capable of effectively penetrating bacteria and fungus.

In this particular scenario, it is important to note that viruses are much smaller in size compared to bacteria. Consequently, in order for the needles to have any impact on viruses, they must be proportionally smaller. The study team conducted an analysis of the theoretical and practical aspects of the mechanism via which viruses lose their infectious capability upon contact with a nanostructured surface.

The interactions between viruses and needles were computer-simulated by Dr. Vladimir Baulin and Dr. Vassil Tzanov at Spain’s Universitat Rovira i Virgili (URV). RMIT researchers exposed the virus to the nanostructured surface and observed the results at the Microscopy and Microanalysis Facility.

The spike design incapacitated 96% of viruses that touched the surface within six hours by damaging their external structure and piercing their membranes. The practicality of the research inspired study first author Samson Mah, who completed the work under an RMIT-CSIRO Masters by Research Scholarship and is now working on his PhD with the team.

“Implementing this cutting-edge technology in high-risk environments like laboratories or healthcare facilities, where exposure to hazardous biological materials is a concern, could significantly improve infectious disease containment,” he said. “We aim to create safer environments for researchers, healthcare professionals, and patients alike.”

Samson W. L. Mah, Denver P. Linklater, Vassil Tzanov, Phuc H. Le, Chaitali Dekiwadia, Edwin Mayes, Ranya Simons, Daniel J. Eyckens, Graeme Moad, Soichiro Saita, Saulius Joudkazis, David A. Jans, Vladimir A. Baulin, Natalie A. Borg, Elena P. Ivanova, 21 December 2023, ACS Nano.

10.1021/acsnano.3c07099

Over two years, researchers from RMIT, URV (Spain), CSIRO, Swinburne University, Monash University, and the Kaiteki Institute collaborated on the project.

The ARC Research Hub for Australian Steel Manufacturing and ARC Industrial Transformational Training Centre in Surface Engineering for Advanced Materials funded this study.

Tech Gadget Central Latest Tech News and Reviews

Tech Gadget Central Latest Tech News and Reviews